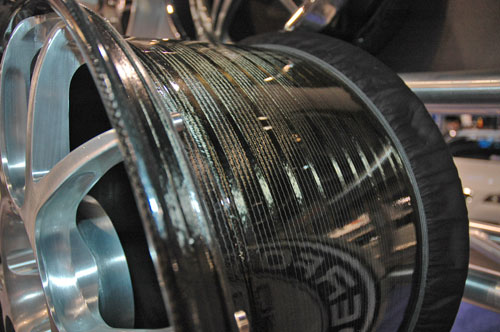

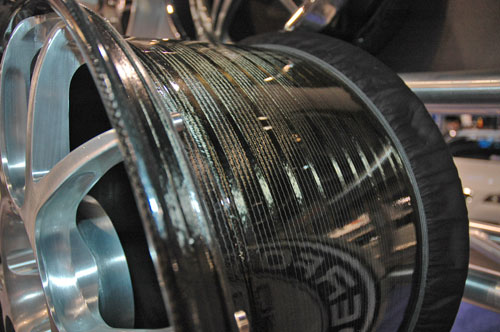

Preview HRE Pre-Production Carbon Fiber Wheels - 专业赛车用品供应商HRE提供碳纤维赛车轮轱

By Carbonfiber.com.cn

In the past we’ve written about Weds 100% carbon fiber wheel, but this is not something that is used in production at this time. Currently, the only real option I know about for a real carbon fiber production wheel is from Dymag, which features a carbon fiber outer rim, and a regular wheel face with magnesium hub. That’s about to change.

Among the manufactures that we met at SEMA this year, HRE announced a partnership with Dymag to create their own set of partially carbon fiber wheels. Dymag has an exclusive partnership with HRE to produce the outer wheel, so you will only see this with them for now.

For those that don’t know of HRE, they are one of the highest end wheel manufacturers in the world. You’ll find their wheels on anything from a BMW M3 to a Lamborghini Murcielago. They are known for making multi-piece forged custom forged wheels with many options to fit your application.

The new carbon fiber wheel is in the final stages of development, and expected to hit the streets in January of 2009. You’ll be able to find them in both the 590R and 890R styles, which feature forged aluminum centers with titanium hardware. They will initially be available in both a 19″ and 20″ wheel, and can be expected to cost $2,500-$4,000/wheel ($10,000-$16,000/set), although final price is yet to be determined.

We spoke with Alan Peltier, HRE’s COO to ask him a few questions about the wheels. The main reason it’s available in only two styles is because of the way they are pre-cut to fit the wheel spoke pattern. They don’t want to start offering carbon wheels across the board due to the cost, so this is sort of considered an initial test of the market. On top of that, using the wheel styles with a lot of spokes offers a good amount of structural integrity. The 20 inch wheel is expected to weigh in at just 21lbs.

When we originally wrote about Weds wheels, we saw a lot of people commenting about worries of carbon fiber bursting under some sort of pressure. Alan posted on a thread at 6SpeedOnline regarding this:

So on to carbon. It turns out that the stiffness of the carbon barrel is actually much higher than the stiffness of the aluminum barrel. In fact, in fatigue, the barrels are load rated MUCH higher than the aluminum center simply because you have to design the rim around impact. Okay… so is it brittle and is it going to shatter into a million pieces under impact. Nope. If you hit a curb or something you’ll definitely damage it, but you’ll have a localized failure which is what you want and should expect.

The way Alan explained it to me at SEMA is that there should be no concerns about the type of damage people where the wheel would basically burst. The wheels are meant for a street/show application, but Alan also said that there were no problems with taking them onto a track if desired.

We’re looking forward to seeing the final version of the wheels, especially installed on some cars. While the wheels from SEMA were aluminum, I’d love to see them in a gunmetal color to better match the carbon fiber. We’ll surely post any updates as we get them.

In the past we’ve written about Weds 100% carbon fiber wheel, but this is not something that is used in production at this time. Currently, the only real option I know about for a real carbon fiber production wheel is from Dymag, which features a carbon fiber outer rim, and a regular wheel face with magnesium hub. That’s about to change.

Among the manufactures that we met at SEMA this year, HRE announced a partnership with Dymag to create their own set of partially carbon fiber wheels. Dymag has an exclusive partnership with HRE to produce the outer wheel, so you will only see this with them for now.

For those that don’t know of HRE, they are one of the highest end wheel manufacturers in the world. You’ll find their wheels on anything from a BMW M3 to a Lamborghini Murcielago. They are known for making multi-piece forged custom forged wheels with many options to fit your application.

The new carbon fiber wheel is in the final stages of development, and expected to hit the streets in January of 2009. You’ll be able to find them in both the 590R and 890R styles, which feature forged aluminum centers with titanium hardware. They will initially be available in both a 19″ and 20″ wheel, and can be expected to cost $2,500-$4,000/wheel ($10,000-$16,000/set), although final price is yet to be determined.

We spoke with Alan Peltier, HRE’s COO to ask him a few questions about the wheels. The main reason it’s available in only two styles is because of the way they are pre-cut to fit the wheel spoke pattern. They don’t want to start offering carbon wheels across the board due to the cost, so this is sort of considered an initial test of the market. On top of that, using the wheel styles with a lot of spokes offers a good amount of structural integrity. The 20 inch wheel is expected to weigh in at just 21lbs.

When we originally wrote about Weds wheels, we saw a lot of people commenting about worries of carbon fiber bursting under some sort of pressure. Alan posted on a thread at 6SpeedOnline regarding this:

So on to carbon. It turns out that the stiffness of the carbon barrel is actually much higher than the stiffness of the aluminum barrel. In fact, in fatigue, the barrels are load rated MUCH higher than the aluminum center simply because you have to design the rim around impact. Okay… so is it brittle and is it going to shatter into a million pieces under impact. Nope. If you hit a curb or something you’ll definitely damage it, but you’ll have a localized failure which is what you want and should expect.

The way Alan explained it to me at SEMA is that there should be no concerns about the type of damage people where the wheel would basically burst. The wheels are meant for a street/show application, but Alan also said that there were no problems with taking them onto a track if desired.

We’re looking forward to seeing the final version of the wheels, especially installed on some cars. While the wheels from SEMA were aluminum, I’d love to see them in a gunmetal color to better match the carbon fiber. We’ll surely post any updates as we get them.