新型碳纤维热塑性复合材料将成为金属替代物

By www.carbonfiber.com.cn

美国复合材料生产商RTP日前宣布,公司已成功推出一款新型碳纤维复合热塑性工程塑料。该塑料采用世界顶尖级合成艺生产而成,在增强材料性能的同时保留了纤维的完整性。

RTP公司将该新型CFRP(碳纤维增强型复合塑料)取名为“彻底高性能复合材料”。据悉,此款新型工程塑料由PEEK(聚醚醚铜)、高性能PPA、PPS(聚苯硫醚)以及PEI(聚醚酰亚胺)多种树脂复合而成。

RTP高性能材料业务部经理Matt Torosian表示,这一新型合材料的问世对热塑性工程塑料行业而言具有里程碑式的意义。“彻底高性能复合材料”将耐高温聚合物与纤维增强型材料有机结合,使新一代工程塑料的性能更加趋近于完美。”Matt Torosian如是说。

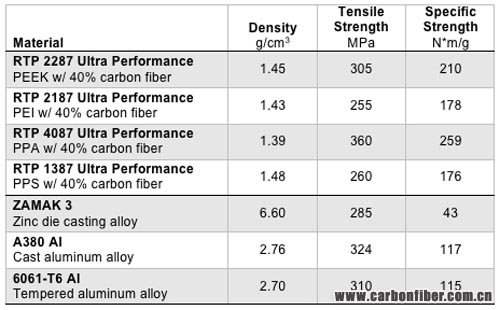

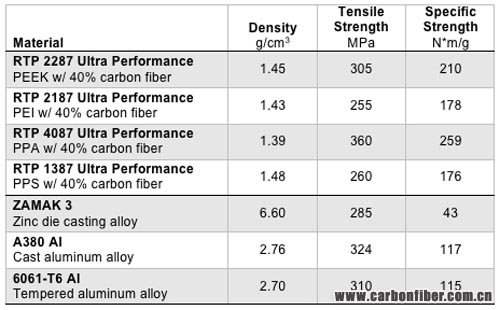

据悉,该新型复合塑料不但具备工程塑料所需的高抗冲击性的机械性能,还继承了碳纤维低密度、耐腐蚀、易成型的优良。在组成成分中,碳纤维的含量为20-40%。

RTP方面称,这一复合材料能够经受高温、高压等极地环境的考验,其在航空、工业、医疗、汽车等领域的应用前景将十分可期。预计在不久的将来,该材料将逐渐取代铝、锌、镁等金属。

Carbon fibre reinforced thermoplastics combine chemical resistance with strength and stiffness

RTP Company : 10 January, 2014 (New Product)

RTP has developed customised thermoplastic compounds in over 60 different engineering resin systems for applications requiring colour, conductive, elastomeric, flame retardant, high temperature, structural, and wear resistant properties. They are based on carbon fibre reinforced PEEK, PPA, PPS, and PEI resin systems to create the highest performing thermoplastic products available.

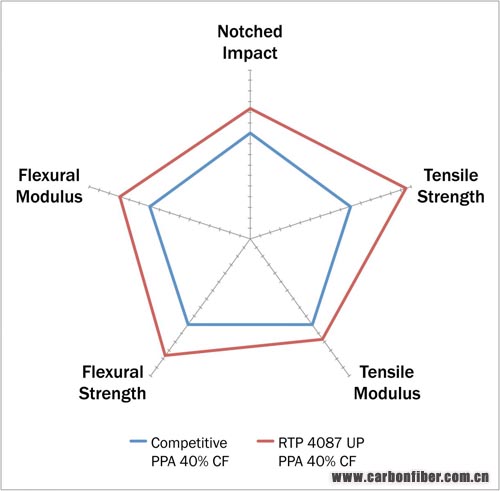

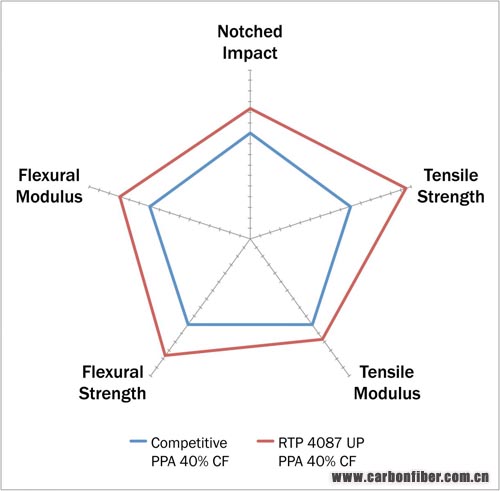

Manufactured using advanced compounding techniques that maximise fibre integrity, the strength and stiffness properties that are higher than previously available products. Combining the higher mechanical properties and lower densities of carbon fibre with the excellent thermal and chemical resistance provided by using high temperature resin systems allows these injection-mouldable thermoplastic materials to close the performance gap between plastics and metals.

Products are available in high temperature resin systems with carbon fibre reinforcement loadings from 20-40% to provide performance options that meet a broad range of requirements for demanding applications in energy, industrial, aerospace, automotive, and medical markets that previously required aluminium, zinc and magnesium.

"These high temperature polymers combine excellent chemical resistance with very high strength and stiffness making them the premier choice for energy exploration, industrial fluid handling, and other applications that are exposed to harsh service environments," said Matt Torosian, High Temperature Product Manager at RTP. "With higher strength and stiffness values along with improved impact and fatigue resistance, these materials provide across the board performance improvements that will give product designers added confidence when specifying Ultra Performance Structural Compounds to replace traditional materials."

In addition to structural characteristics, RTP can incorporate other capabilities during compounding, such as wear and friction resistance at high pressure/velocity ratios without needing external lubricants. PEEK, PEI, and PPS materials are inherently flame retardant and often chosen for their low burning toxicity, but flame retardants can also be added to PPA to increase product safety.Carbon fibre reinforced thermoplastics combine chemical resistance with strength and stiffness

RTP’s has developed customised thermoplastic compounds in over 60 different engineering resin systems for applications requiring colour, conductive, elastomeric, flame retardant, high temperature, structural, and wear resistant properties. They are based on carbon fibre reinforced PEEK, PPA, PPS, and PEI resin systems to create the highest performing thermoplastic products available.

Manufactured using advanced compounding techniques that maximize fibre integrity, the strength and stiffness properties that are higher than previously available products. Combining the higher mechanical properties and lower densities of carbon fibre with the excellent thermal and chemical resistance provided by using high temperature resin systems allows these injection-mouldable thermoplastic materials to close the performance gap between plastics and metals.

Products are available in high temperature resin systems with carbon fibre reinforcement loadings from 20-40% to provide performance options that meet a broad range of requirements for demanding applications in energy, industrial, aerospace, automotive, and medical markets that previously required aluminium, zinc and magnesium.

"These high temperature polymers combine excellent chemical resistance with very high strength and stiffness making them the premier choice for energy exploration, industrial fluid handling, and other applications that are exposed to harsh service environments," said Matt Torosian, High Temperature Product Manager at RTP. "With higher strength and stiffness values along with improved impact and fatigue resistance, these materials provide across the board performance improvements that will give product designers added confidence when specifying Ultra Performance Structural Compounds to replace traditional materials."

In addition to structural characteristics, RTP can incorporate other capabilities during compounding, such as wear and friction resistance at high pressure/velocity ratios without needing external lubricants. PEEK, PEI, and PPS materials are inherently flame retardant and often chosen for their low burning toxicity, but flame retardants can also be added to PPA to increase product safety.

环球塑化网

美国复合材料生产商RTP日前宣布,公司已成功推出一款新型碳纤维复合热塑性工程塑料。该塑料采用世界顶尖级合成艺生产而成,在增强材料性能的同时保留了纤维的完整性。

RTP公司将该新型CFRP(碳纤维增强型复合塑料)取名为“彻底高性能复合材料”。据悉,此款新型工程塑料由PEEK(聚醚醚铜)、高性能PPA、PPS(聚苯硫醚)以及PEI(聚醚酰亚胺)多种树脂复合而成。

RTP高性能材料业务部经理Matt Torosian表示,这一新型合材料的问世对热塑性工程塑料行业而言具有里程碑式的意义。“彻底高性能复合材料”将耐高温聚合物与纤维增强型材料有机结合,使新一代工程塑料的性能更加趋近于完美。”Matt Torosian如是说。

据悉,该新型复合塑料不但具备工程塑料所需的高抗冲击性的机械性能,还继承了碳纤维低密度、耐腐蚀、易成型的优良。在组成成分中,碳纤维的含量为20-40%。

RTP方面称,这一复合材料能够经受高温、高压等极地环境的考验,其在航空、工业、医疗、汽车等领域的应用前景将十分可期。预计在不久的将来,该材料将逐渐取代铝、锌、镁等金属。

Carbon fibre reinforced thermoplastics combine chemical resistance with strength and stiffness

RTP Company : 10 January, 2014 (New Product)

RTP has developed customised thermoplastic compounds in over 60 different engineering resin systems for applications requiring colour, conductive, elastomeric, flame retardant, high temperature, structural, and wear resistant properties. They are based on carbon fibre reinforced PEEK, PPA, PPS, and PEI resin systems to create the highest performing thermoplastic products available.

Manufactured using advanced compounding techniques that maximise fibre integrity, the strength and stiffness properties that are higher than previously available products. Combining the higher mechanical properties and lower densities of carbon fibre with the excellent thermal and chemical resistance provided by using high temperature resin systems allows these injection-mouldable thermoplastic materials to close the performance gap between plastics and metals.

Products are available in high temperature resin systems with carbon fibre reinforcement loadings from 20-40% to provide performance options that meet a broad range of requirements for demanding applications in energy, industrial, aerospace, automotive, and medical markets that previously required aluminium, zinc and magnesium.

"These high temperature polymers combine excellent chemical resistance with very high strength and stiffness making them the premier choice for energy exploration, industrial fluid handling, and other applications that are exposed to harsh service environments," said Matt Torosian, High Temperature Product Manager at RTP. "With higher strength and stiffness values along with improved impact and fatigue resistance, these materials provide across the board performance improvements that will give product designers added confidence when specifying Ultra Performance Structural Compounds to replace traditional materials."

In addition to structural characteristics, RTP can incorporate other capabilities during compounding, such as wear and friction resistance at high pressure/velocity ratios without needing external lubricants. PEEK, PEI, and PPS materials are inherently flame retardant and often chosen for their low burning toxicity, but flame retardants can also be added to PPA to increase product safety.Carbon fibre reinforced thermoplastics combine chemical resistance with strength and stiffness

RTP’s has developed customised thermoplastic compounds in over 60 different engineering resin systems for applications requiring colour, conductive, elastomeric, flame retardant, high temperature, structural, and wear resistant properties. They are based on carbon fibre reinforced PEEK, PPA, PPS, and PEI resin systems to create the highest performing thermoplastic products available.

Manufactured using advanced compounding techniques that maximize fibre integrity, the strength and stiffness properties that are higher than previously available products. Combining the higher mechanical properties and lower densities of carbon fibre with the excellent thermal and chemical resistance provided by using high temperature resin systems allows these injection-mouldable thermoplastic materials to close the performance gap between plastics and metals.

Products are available in high temperature resin systems with carbon fibre reinforcement loadings from 20-40% to provide performance options that meet a broad range of requirements for demanding applications in energy, industrial, aerospace, automotive, and medical markets that previously required aluminium, zinc and magnesium.

"These high temperature polymers combine excellent chemical resistance with very high strength and stiffness making them the premier choice for energy exploration, industrial fluid handling, and other applications that are exposed to harsh service environments," said Matt Torosian, High Temperature Product Manager at RTP. "With higher strength and stiffness values along with improved impact and fatigue resistance, these materials provide across the board performance improvements that will give product designers added confidence when specifying Ultra Performance Structural Compounds to replace traditional materials."

In addition to structural characteristics, RTP can incorporate other capabilities during compounding, such as wear and friction resistance at high pressure/velocity ratios without needing external lubricants. PEEK, PEI, and PPS materials are inherently flame retardant and often chosen for their low burning toxicity, but flame retardants can also be added to PPA to increase product safety.

环球塑化网